Posts tagged work

3D Storytelling 2012

3D Storytelling is one of the biggest events of the year at Ravensbourne. The event is totally different from any other that is run within Ravensbourne as it is headed up by the events team and is run by a select group of students. This year Russell Fleming and Myself took on all of the events logistics and rigging with Tom Glover creating the lighting design. The event features around the fact that there is a RealD Projector in the walker space that allows speakers from different companies to show off there work to the rest of the 3D television and film industry. This gives the students a platform to network with people form within industry as nearly 1000 delegates turn up across the 2 day event.

My role for 3D storytelling was as head of rigging and logistics, Russell was head of event technology and logistics, both of us have these roles for Ravensbourne 2012. The main rigging requirements for this event were to light the walker space for the keynote speeches, light the building to give it a different look and feel and put power distribution on the 4th floor for the exhibition.

To start with I worked out the power requirements for the exhibition going off a floor plan with 22 stalls on it. This time I decided to use the 125 Amp 3Phase on level 5 and split it down to 2 63 Amp 3Phase’s as we had some high power lights for the architectural lighting. The distro’s that we went with were 125A 3P to 2 x 63A 3P and 2 x 63A 3P to 18 x 16A. This meant that I had more than enough outputs for all of the lighting requirements and if all of the stalls were used. We also made the decision to cut the 4 way extensions down to 2 as it was felt that they only need 2 sockets per stall.

For the lighting side of the rigging Tom had asked for 4 city colour washes to go on level 7 and 4 to go on level 4 along with 2 Clay Paky 1200 spots to go at each location. The Clay Paky’s on level 7 had to be hung to get good coverage on the wall. Originally I wanted to hang them off a truss rigged to the RSJ’s above level 9 but as we did not have a load testing certificate to say what load they could take health and safety did not like the idea. I then decided to put them on 2 wind up stands on the 7th floor. The lighting for the main atrium was originally going to go on the 4th floor but was deemed to be in the fire lane and had to be moved when once it had been put in place. We had to move it to the 1st floor/Mezz which actually created some nicer angles and gave a really nice look on the final night when the networking was taking place in the welcome space. All of these lights were sitting on 3ft high deck so that the metal grill under the railing did not get in the way.

In the walker space we felt that we had to do something different from what had been done before in that space. We ended up dead hanging a scaff bar and putting par cans up for a wash of colour along with source 4’s with gobo break ups in them, for once no movers were used. This all ran of the house dimmer pack saving a lot of money and time.

The biggest challenge that Russell and myself had in the planning stage of this event was where to put a Telegenic OB truck. This is a major problem as the outside of Ravensbourne is not designed to have a truck of this size sitting there for over 2 days. This caused major problems right up until the last minute as every location that we chose there was something causing a problem. In the end we got parked it down the side of Rave. I feel proud at the amount of contacts that Russell and myself made out of this event, some of which involved people that generally students don’t even know about. I also made sure that I did not make the same mistakes that I made at penrose market. The logistics generally ran very smoothly with no major problems. This is due to the time and care that Russell and myself put in and the communication with the management of the event. I have to give a big thank you to the second rigging team as they managed to gel over 250 florescent lights around Rave to change the colour of the building.

Penrose Market Fly Away CAD

For the Penrose Market last week we had to create a complete studio in a Rack called a Fly Away. We had to create this Fly Away because the studio facilities at Ravensbourne were in use for another shoot on the same day.

This Fly Away was created using any available kit that we found on Level 9, then using the time in our 208 and 204 lectures to design and build the system with the help of James Uren and the rest of the BET Pathway. After an initial brain storm and specification we came up with a simple system that consisted of:

- 7 SD Cameras

- 1 VT Deck

- 1 16 Channel Vision Mixer

- 1 16×1 Router

- CTP and Jack Field

- 3 Digital DA’s – 1 Analogue DA in the Fly Away

- 8 Digital DA’s – 4 Digital to Analogue Converters in the Monitor Stack

- 10 Monitors

- 1 Large Engineering Monitor

- 1 Test Pattern Genorator

- 2 Wave Form Monitors

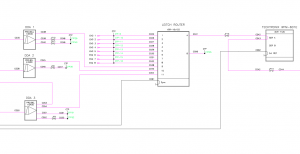

The initial brainstorm and scribbled drawing was then drawn up, neatly, onto a large A1 sheet of paper, along with a Cable Schedule and CTP / Jack Field layouts. This large Drawing was then attached to the side of the rack and used as a reference throughout the rest of the project.

After the project was completed on Tuesday (22/11/2011) we were required as part of our Hardware Systems unit (204) to draw up a full CAD in AutoCad based on the same layers and components that were used to create the CAD’s for the main system in Ravensbourne. This exercise was designed to teach us how to use CAD to create Technical Drawings as well as be confident in reading and updating existing drawings. A screen shot of mine can be found on the right, with a PDF copy of the final cad available for download below.

After the project was completed on Tuesday (22/11/2011) we were required as part of our Hardware Systems unit (204) to draw up a full CAD in AutoCad based on the same layers and components that were used to create the CAD’s for the main system in Ravensbourne. This exercise was designed to teach us how to use CAD to create Technical Drawings as well as be confident in reading and updating existing drawings. A screen shot of mine can be found on the right, with a PDF copy of the final cad available for download below.

The technical drawing we had to create was in fact two drawings of two separate systems which interacted closely with each other. The first was the main Fly Away, which was a single rack with all the processing and routing required, and the second was of the Monitor Stack which was required to make the Rack work. This is a major problem with the system as it require one part to work to make the rest work, whilst also doubling the amount of video connections in and out of the rack. However these problems were only noticed after the initial and were not a problem in this project as the monitor stack and rack were being built side-by-side at the same time.

Having so many connection to and from the rack also opened up another problem, which could simply be caused by confusion during the connection of the rack to the video sources and the monitor stack. This confusion could lead to video being sent the wrong way into the system, which could cause damage to equipment, or for example a Camera could be fed into one of the ENG inputs, thus it would appear to work fine on the router but it would have completely bypassed the monitor stack and more importantly the Vision Mixer.

Above I talked about just a few of the problems with last weeks Fly Away, in time I may look into re-drawing the Technical Drawing to alleviate some of the faults mentioned, and when I have re-drawn a new version of the system I will post a comparison between the two.

Download an A1 PDF of my Technical Drawing Here.

Download a PDF copy of my Cable Schedule Here.

LECTURE: IPP

0Presentation and Communication skills both, crucial for this industry, if your not a clear communicator or team worker you wont get much work in this industry. Communication is more important than technical ability in most roles, if you cannot clearly communicate the problem to another team worker, they cannot assist you through the situation.

Presentations skills are also key to getting work, as how you present yourself to a future employer is critical, as they say first impressions last. Presentations skills are also key for Producers and Operations students, when pitching there ideas to networks, and financiers.